SIS FORM Division

SIS FORM Division

-

Construction method introduction video

-

SIS FORM method

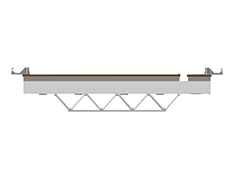

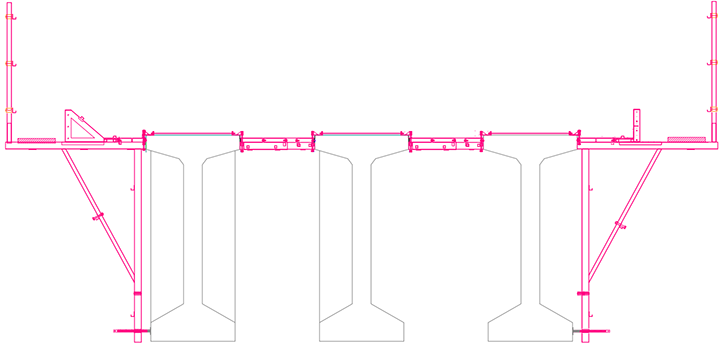

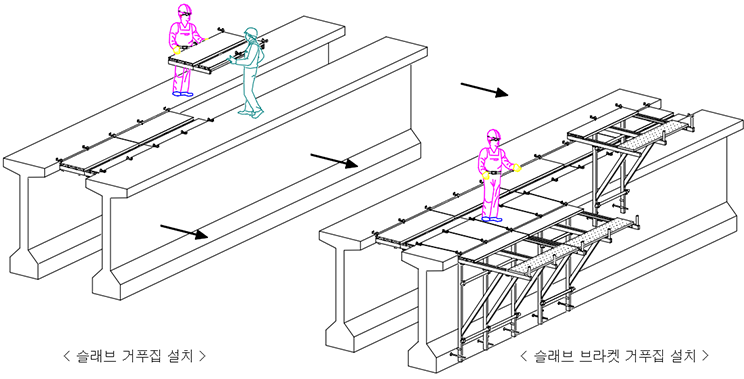

When pouring concrete on the top of a bridge or road overpass, the formwork can be installed without installing a girder between the girder and the integrated formwork panel construction method that facilitates handling and freely expands or reduces the size of the formwork.

Construction

- As the process is simplified by the integration of the copper bar and the formwork, the work efficiency is increased and even the unskilled can easily and quickly perform the construction.

Safety

- This product is installed in a confined space during slab formwork and can be used as a pathway for workers to secure safety against the risk of falling.

Efficiency

- Reduced construction cost by 30% compared to the existing construction method by minimizing the number of workers and reducing costs through product reuse due to the simplified process steps

-

Product Features

Applicable to all bridge slabs

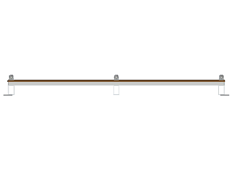

Transport and quick installation and disassembly are easy with an all-in-one system with copper bars and molds.

The width can be adjusted, so it can be installed and used in places where the girder spacing is not uniform.

Safety is secured by preventing the risk of falling because the operator can use it as a moving passage

-

Central slab formwork construction sequence

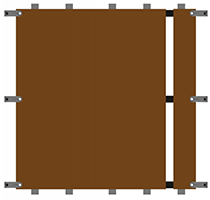

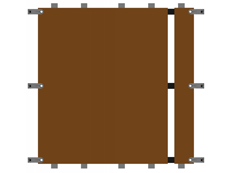

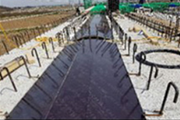

⟨Central slab formwork lifting⟩

⟨Conveying central slab formwork⟩

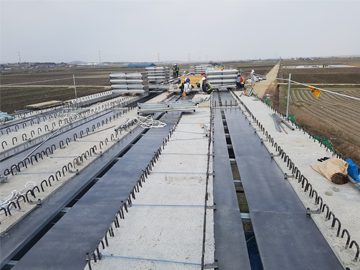

⟨Central slab formwork installation⟩

⟨TIE-BOLT connection between casting brackets⟩

⟨Completed installation of central slab formwork⟩

⟨Central slab finish treatment⟩

-

Comparison of construction method and construction cost

This product SIS formwork construction method

Unlike conventional formwork, this product is easy to install and disassemble quickly as it is an integrated system of copper and formwork without assembling process of dogwood, joist, square, and plywood.

Unlike conventional formwork, this product is easy to install and disassemble quickly as it is an integrated system of copper and formwork without assembling process of dogwood, joist, square, and plywood.

-

Construction cost comparison

SIS FORM, plywood formwork, precast panel construction cost comparison table

1.Bridge type: PSC Beam 45m @6 rows (Girder spacing: 2,200-Girder upper width: 1,200)

2. Bridge extension: L = 45+45 = 90m upper formwork area 654m²division standard unit Standard parting Precast Deck Method Plywood formwork SIS FORM method Remark unit price Quantity Price unit price Quantity Price unit price Quantity Price unit price Quantity Price Central section Formwork Plywood 3 times ㎡ 49,363 438 21,620,994 28,659 47 1,346,973 28,659 438 12,552,618 28,659 40 1,146,358 Dongbari wood ㎥ 36,425 900 32,782,500 - 20,407 900 18,366,642 - Slab

SIS FORMSlab ㎡ - - 40,934 396 16,210,000 Precast Deck Slab ㎡ 93,630 391 36,609,330 Cantilever section Formwork Plywood 3 times ㎡ 49,363 108 5,331,204 32,314 4 129,256 32,314 108 3,489,914 32,314 2 64,628 Dongbari

(Deck Finisher)Deck Finisher ㎥ 20,703 216 4,471,848 - 21,100 216 4,557,533 - Cantilever part

SIS FORMCantilever part ㎡ - - 104,815 108 11,320,000 Precast Deck Cantilever part ㎡ 93,630 104 9,737,520 Direct construction scaffolding 64,206,546 47,823,079 38,966,708 28,740,986 Construction rate 223% 166.40% 135.60% 100% * In the case of precast panels, since there is no basis for calculating the unit price of the cantilever unit, the unit price of the slab was applied.

* Actual construction costs may vary depending on the conditions of the site, such as equipment and personnel.