Atmospheric Environmental Business Department

White smoke reduction device

Industrial Filter Dust Collector

Counter-Steam Device

for Hot Water Pipes Fog damage prevention business

for Hot Water Pipes Fog damage prevention business

-

Technology introduction video

-

Background of mobile white smoke reduction device development

Case of white smoke damage due to hot water leakage

Limited visibility due to white smoke in the workplace

Limited visibility due to white smoke in the workplace

Traffic paralysis caused by white smoke

Traffic paralysis caused by white smoke

Delayed search for heating piping damaged by white smoke

Delayed search for heating piping damaged by white smoke

Recently, hot water leakage accidents in which the piping is ruptured due to damage to the heating piping due to frequent road excavation have been frequent.

Recently, hot water leakage accidents in which the piping is ruptured due to damage to the heating piping due to frequent road excavation have been frequent.

When excavating the ground of a pipe buried for repair, a large amount of white smoke is generated by meeting external cold air.

Due to the difficulty of ensuring visibility of workers due to the generated white smoke, the search for damaged pipes is delayed, and it is difficult to secure visibility for drivers and pedestrians.In the worst case, hot water supply must be stopped and maintenance work must be carried out.

In addition, due to the difficulty of securing workplace safety due to vapor-based white smoke in various industrial sites, there is an urgent need to cope with this.

We developed a mobile white smoke reduction device to enable rapid response through cooperation with Korea District Heating Corporation.

-

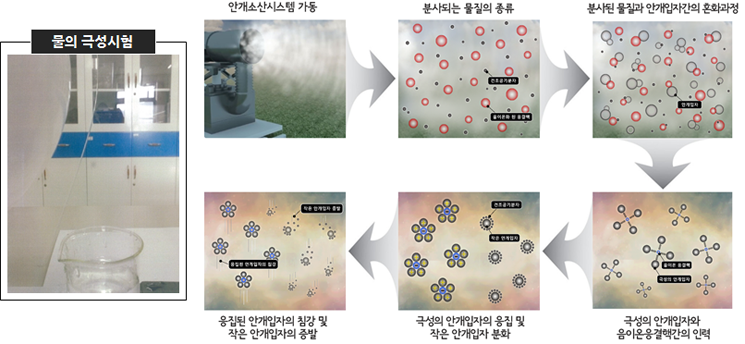

기술 원리

Existing method is a method of pushing white smoke with a blower. If a large amount of white smoke is continuously generated, even if a large amount of white smoke is used, the peripheral vision becomes more severe due to the scattering of white smoke, and it cannot be applied in a closed space such as a manhole.

Existing method is a method of pushing white smoke with a blower. If a large amount of white smoke is continuously generated, even if a large amount of white smoke is used, the peripheral vision becomes more severe due to the scattering of white smoke, and it cannot be applied in a closed space such as a manhole.

Nuriplan Co., Ltd.'s mobile white smoke reduction device sprays dry air and negative ion condensed nuclei, which allows for white smoke removal more quickly and reliably than the existing method by agglomeration, precipitation and evaporation through mixing with white smoke particles.

-

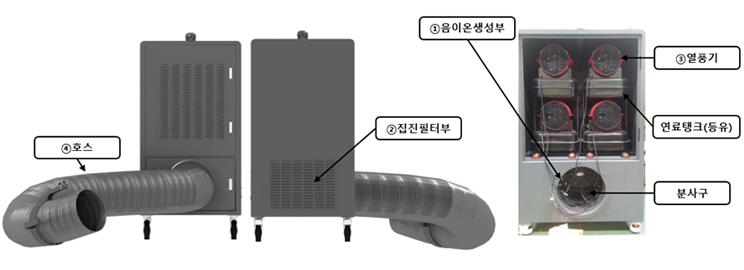

Technology composition and processing

①Anion generation unit: More than 1 million negative ions are released per second from the negative ion generator, and these particles are combined with the coagulation nuclei generated by the hot air to generate anion coagulation nuclei.

①Anion generation unit: More than 1 million negative ions are released per second from the negative ion generator, and these particles are combined with the coagulation nuclei generated by the hot air to generate anion coagulation nuclei.

②Dust-collecting filter unit: A filter that primarily collects particulate matter before external air enters the hot air, and the effect of suppressing the scattering of surrounding dust when using a portable white smoke reduction device

③Hot air fan: Dry air by heating air through combustion of fuel, particles generated during combustion generate condensation nuclei

④Hose: Sprays dry negative ion condensed nuclei discharged through the nozzle toward the point where white smoke is generated

-

Advantages of technology

The world's first technology to remove white smoke by agglomerating and sedimenting white smoke particles by spraying ultra-low humidity air and negative ion condensed nuclei

The world's first technology to remove white smoke by agglomerating and sedimenting white smoke particles by spraying ultra-low humidity air and negative ion condensed nuclei

It is not a method of spreading white smoke by a simple blowing method, but a technology that removes white smoke from the source, so it can be used in a closed space.

Miniaturization (possible to load a 1-ton truck) and mobile (with wheels) increase user convenience and enable quick response to areas where white smoke occurs

A variable flexible bellows installed at the nozzle and a handle and a rental turn at the end greatly improves operator accessibility even at night.

Product design to facilitate inspection and repair during maintenance with product modularization

-

Target of the technology

Chimney

ironworks

ironworks

Textile factory

Textile factory

Cogeneration

Cogeneration

Dyeing factory

Dyeing factory

Paint factory

Paint factory

Damage to heat (steam) transport pipes Minimizes public heating inconvenience by providing quick removal of white smoke to recover in the shortest time and prevents secondary damage from damage to other underground facilities caused by excavation work

Damage to heat (steam) transport pipes Minimizes public heating inconvenience by providing quick removal of white smoke to recover in the shortest time and prevents secondary damage from damage to other underground facilities caused by excavation work

In order to relieve safety accidents and traffic inconvenience, our products are being used to remove white smoke from leakage of facilities in the construction section of the heat transport pipe.

Possible to prevent safety accidents caused by difficulty in securing visibility due to white smoke occurring in various industrial sites

It can also be used to remove white smoke from power plants and factory chimneys to create a pleasant urban landscape and environment, and can be applied to overall areas where white smoke is generated.

-

Main performance

Various industrial sites such as Korea District Heating Corporation, Seoul Energy Corporation, GS Power and paper maker Pulper

Various industrial sites such as Korea District Heating Corporation, Seoul Energy Corporation, GS Power and paper maker Pulper

-

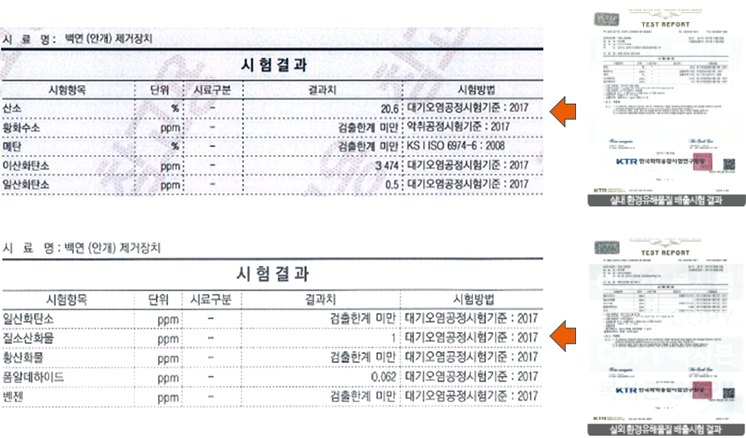

Test report: Emission evaluation of environmentally hazardous substances – Below standard

-

certification

Patent NO 10-1556780

Patent NO 10-1559546

Patent NO 10-1559550

Patent NO 10-1560777

Patent NO 10-1811429

-

Awards and articles

National Prime Minister Award

Newspaper article

GD mark certification in 2017